Product Inventory Management in Hyper Inventory

Inventory Management plays a crucial role in any E-commerce Business. Hyper Inventory provides you with the functionalities which is required for product inventory. This functionalities consist of handling opening stock, tracking available quantities, and the status of products in multiple warehouses.

Opening Stock: It's the amount of a product you have on hand when you add it to your records for the first time. This information helps you keep track of how much of the product each warehouse had initially, at what rate it was acquired, and how well it was managed in the inventory.

You can add the Opening Stock Manually:

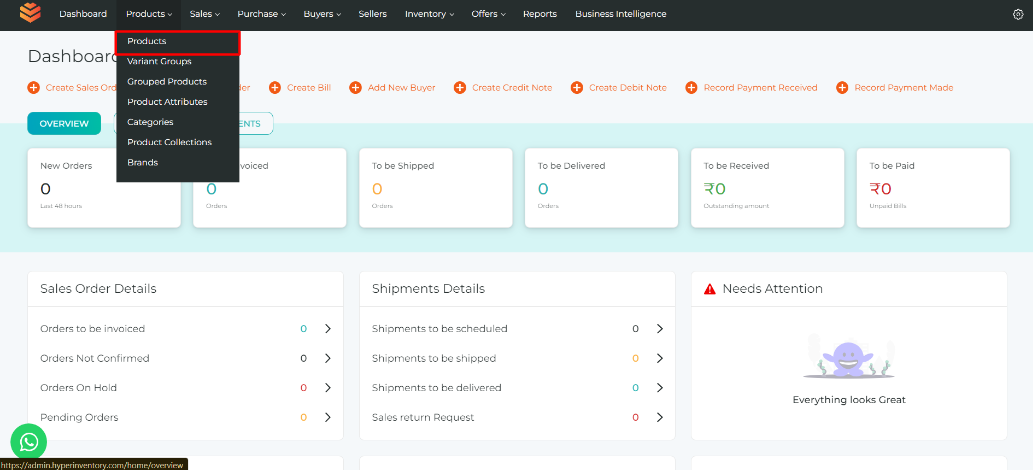

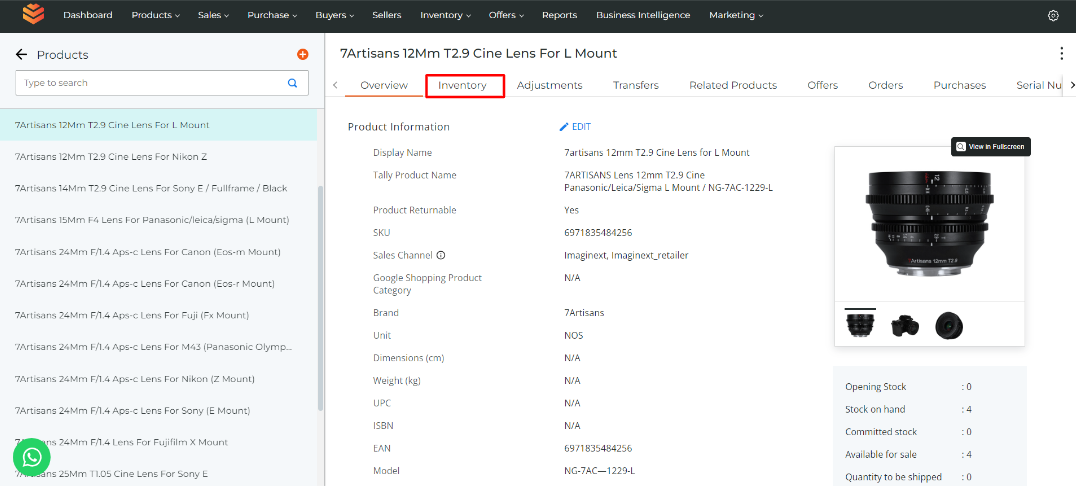

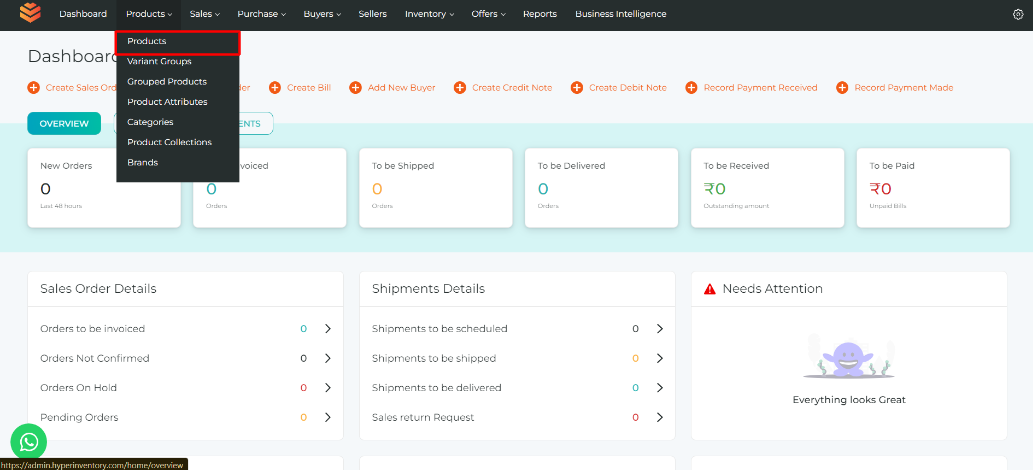

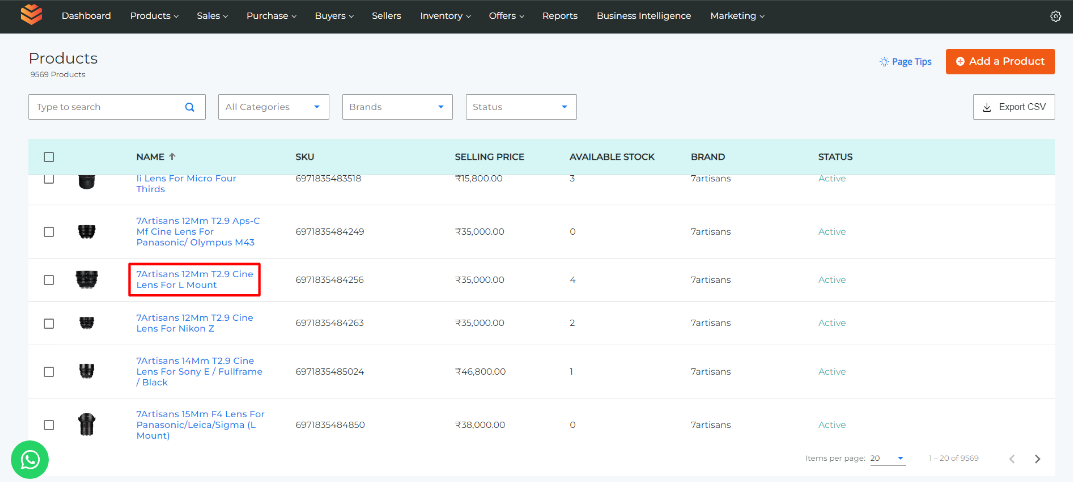

Step 1: Click on products from the Product Listing Section

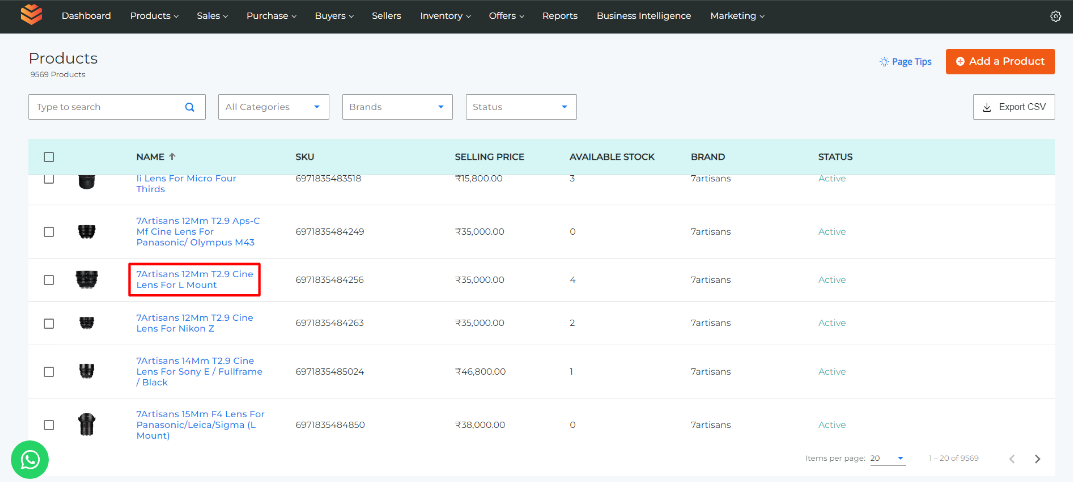

Step 2: Select the product of which you want to Add the opening stock of.

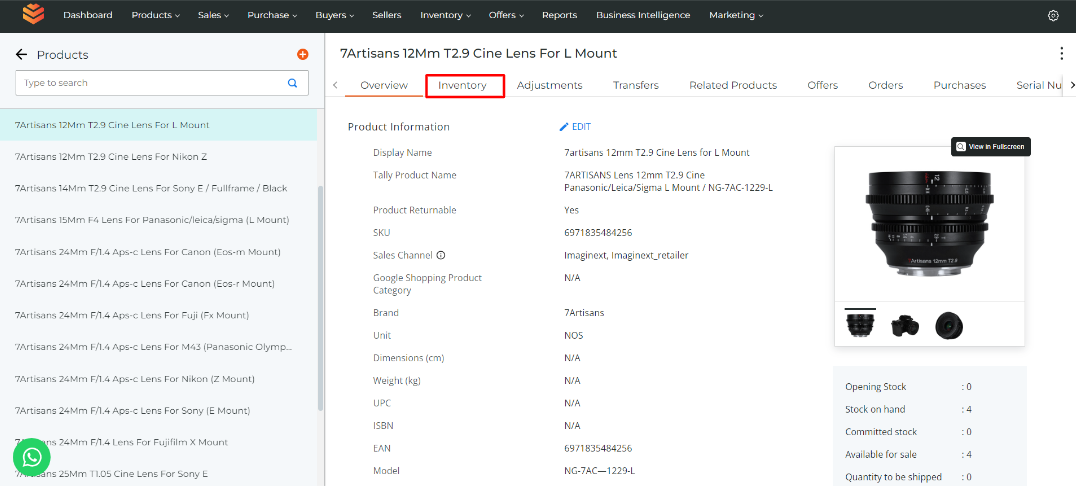

Step 3: Click on "Inventory" in the product information section.

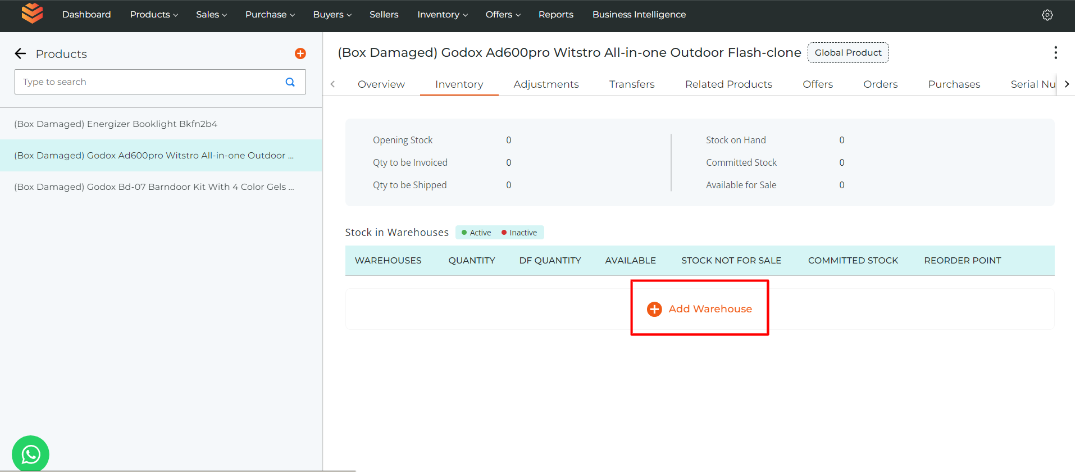

Step 4: Click on "Add Warehouse" and select the warehouse in which you want to add opening stock.

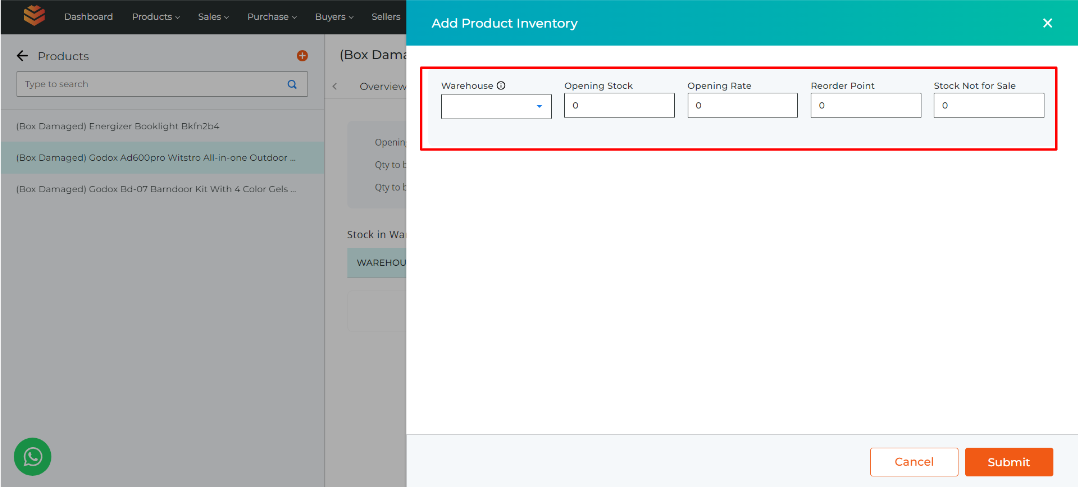

Step 5: Now add the Inventory/Opening Stock of the product:

- Select Warehouse in which you want to add the inventory of the product.

- Add the "Opening Stock" of the product.

- Add the "Opening Rate" of the product.

- Add the reorder point of the product where you would get notified that the stock is less and when you need to order for more.

- Add the quantity of the product which is not for sale and then click on submit.

Your Opening Stock/Inventory of the Product will be added.

Stock on Hand: It simply means the total quantity of goods or products that a business currently has in its inventory, taking into account all its warehouses. This metric helps businesses get a clear picture of the overall availability of stock, considering the combined inventory from all locations.

This will be automatically calculated by Hyperinventory based on the total products and out of that how many were sold, the remaining products is stock on hand.

Qty to be invoiced: Qty to be invoiced refers to the quantity of a product for which an order has been placed, but the corresponding invoice has not been generated yet. This term is used to indicate the amount of products that have been purchased, but the official billing document (invoice) hasn't been created. It helps businesses keep track of pending invoicing for better financial and inventory management, providing insight into outstanding transactions that are yet to be finalized.

This will automatically calculated by Hyperinventory based on how many orders are placed and out of that how many orders are not invoiced.

Qty to be Shipped: "Qty to be shipped" refers to the quantity of a product for which an order has been placed, an invoice has been generated, but the items have not yet been shipped. This term helps in keeping track of products that have been purchased, the associated invoice has been created, but the shipping process is pending. It provides a clear indication of the number of items that need to be prepared and dispatched to fulfill the customer's order, facilitating efficient order fulfillment and inventory management.

This will automatically calculated by Hyperinventory based on how many orders are placed and out of that how many orders are not invoiced.

Committed Stock: "Committed stock" refers to a portion of inventory that has been allocated or reserved for a specific purpose, making it unavailable for general sale or use. It is set aside to fulfill specific orders, commitments, or internal needs. By adding stock to the "Committed" category, businesses ensure that a certain quantity of products is designated for specific use and doesn't contribute to the available stock on hand. This helps in accurately reflecting the inventory available for general sale while also meeting specific obligations or requirements without the risk of overselling or using reserved stock for other purposes.

Available for Sale: "Products available for sale" refer to the inventory or goods that a business currently has in stock and is ready to be sold to customers. This metric is used to assess the quantity of stock available for general sales, excluding any stock that is not intended for sale or has been reserved for specific purposes. The figure includes the total stock across all warehouses, providing a comprehensive view of the products that are actively ready for purchase by customers. It's a crucial measure for businesses to gauge their immediate selling potential and manage their sales operations effectively.

This will automatically calculated by Hyperinventory based on how many procducts are sold & committed and the number of products remaining after that is available for sale.

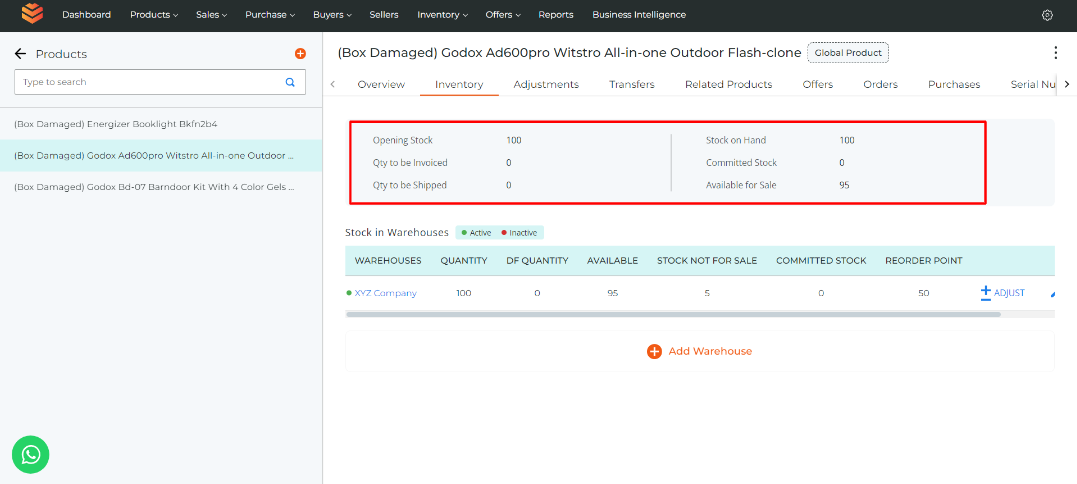

You can check Stock on Hand, Oty to be Invoiced, Qty to be Shipped, Committed Stock & Available for Sale here :

Step 1: Click on "Products" from the Product Listing Section.

Step 2: Select the product of which you want to Check the stock on Hand of.

Step 3: Click on "Inventory" in the product information section.

Step 4: Here you can check the Stock on Hand of the product.

You can Edit/Adjust your Inventory here.

You can add/assign Inventory in Bulk:

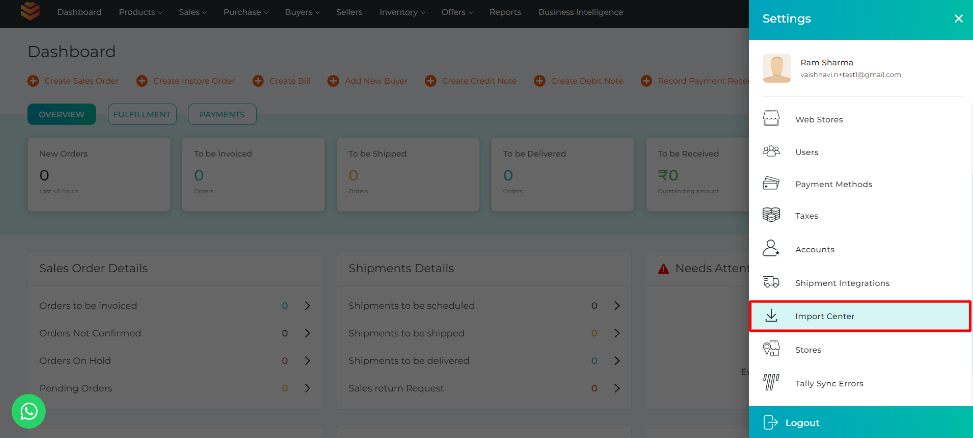

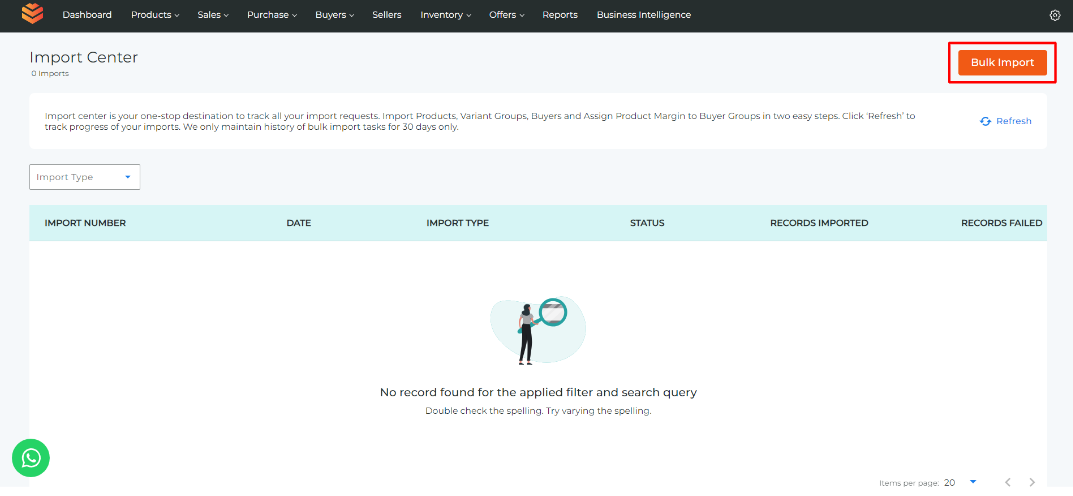

Step 1: Go to settings & click on "Import Center".

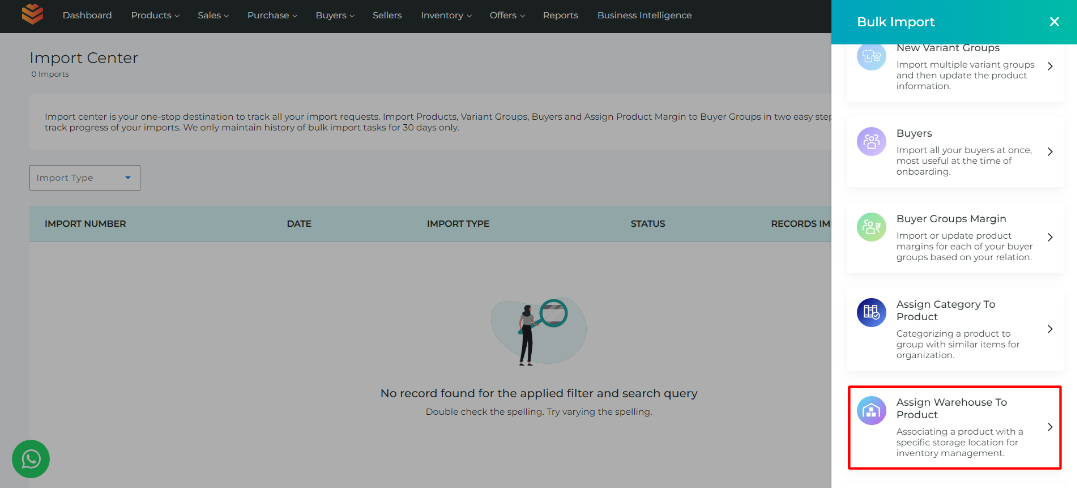

Step 2: A page where all the previous imports that you've made will be displayed. Click on "Bulk Import" Button which is on the top most right hand side on the page. A list of the types of Import that you can make will be displayed.

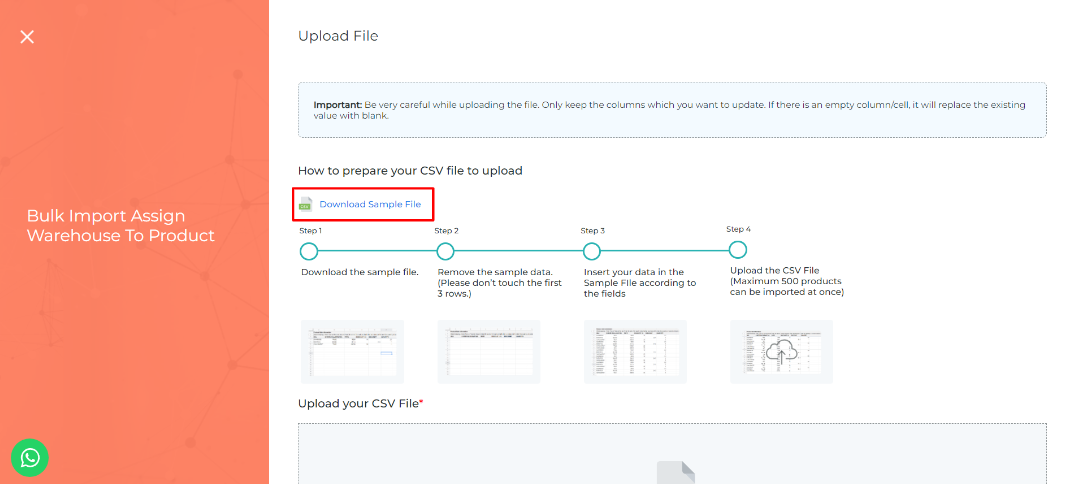

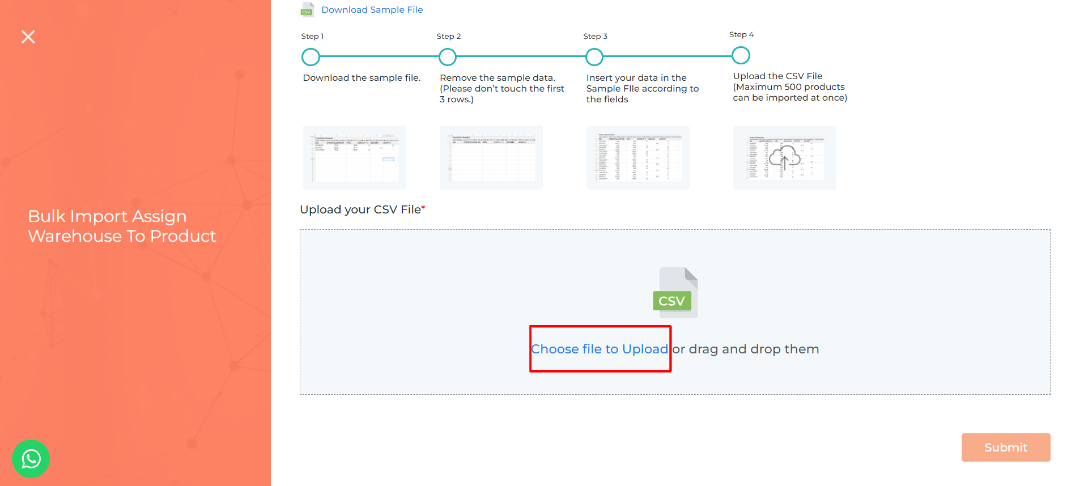

Step 3: Select the "Bulk Assigning Warehouse to Product" option which will lead you to Upload File page.

Step 4: Download the Sample CSV File.

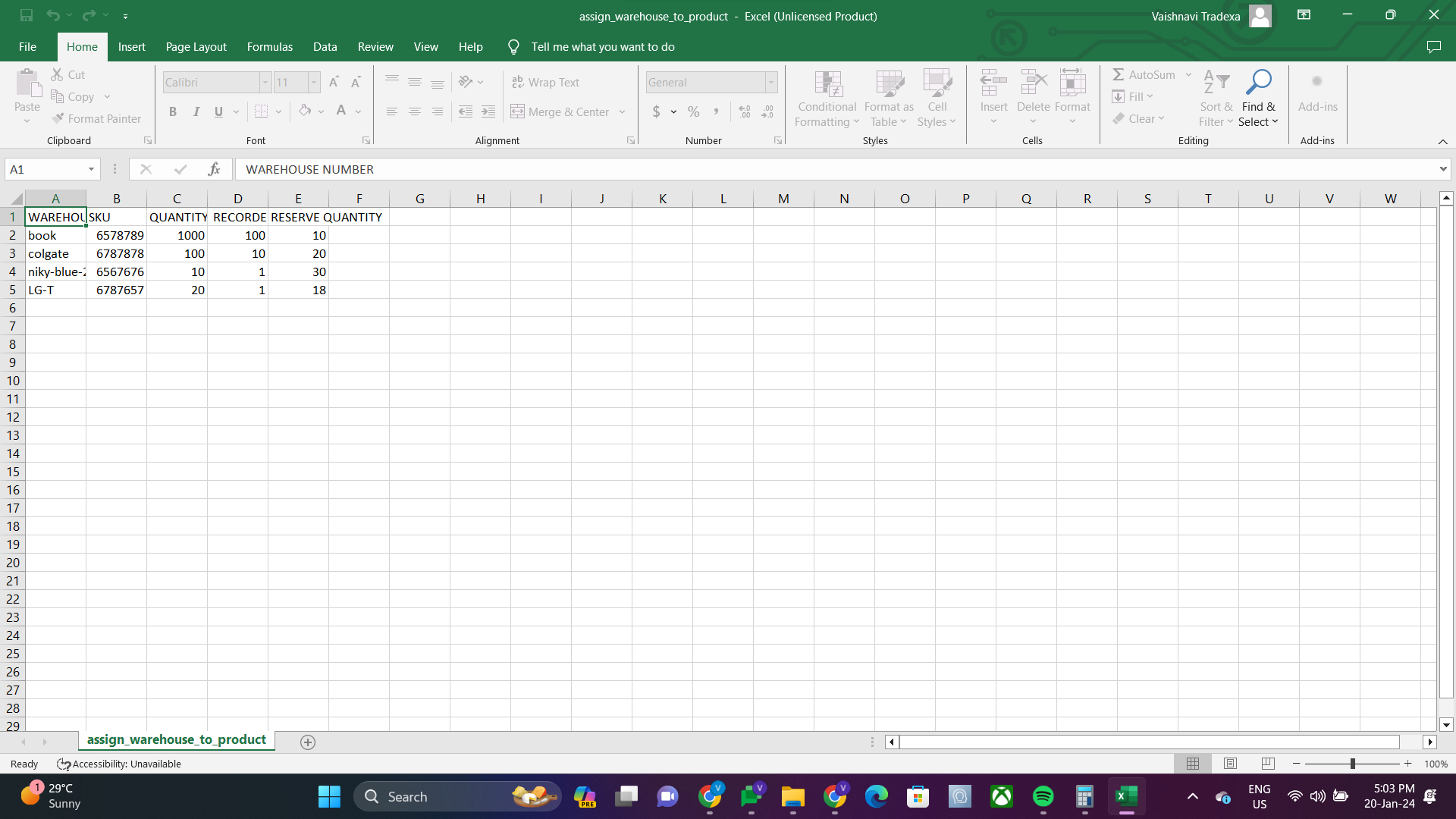

Step 5: Remove the sample data and add the Warehouse name to which you want to assign the products and the SKU of the products. You can add the quantity, reorder point and the reserve quantity as well.

Step 6: Save the file in CSV and import it in the "Upload your CSV File" section on Hyperinventory from where you downloaded the sample file.

Your Inventory will be updated.

1. Do Not change the order of the columns

2. Erase the whole column of which you don't want information to be imported/updated.

3. It will take some time for the inventory to be reflected in your account.

Inventory Transfer

An Inventory Transfer or Warehouse Transfer, is when goods are transported from one warehouse location to another.

Create an Inventory Transfer:

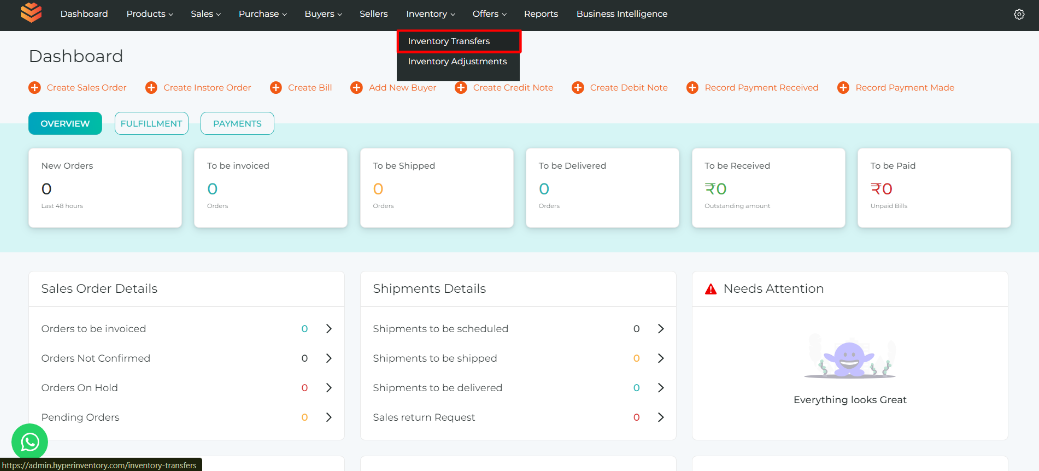

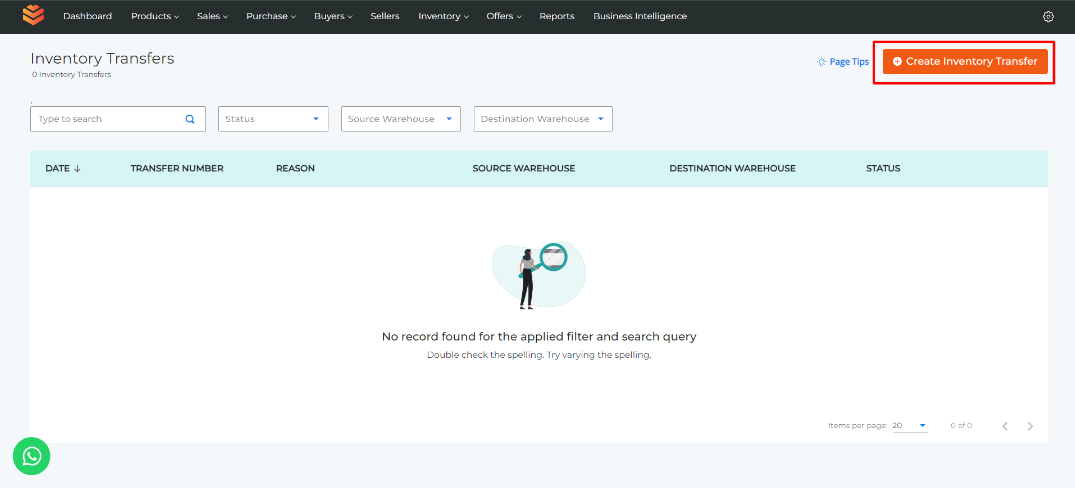

Step 1: Go to the Inventory option from top bar. Select Inventory Transfer option from the drop down menu.

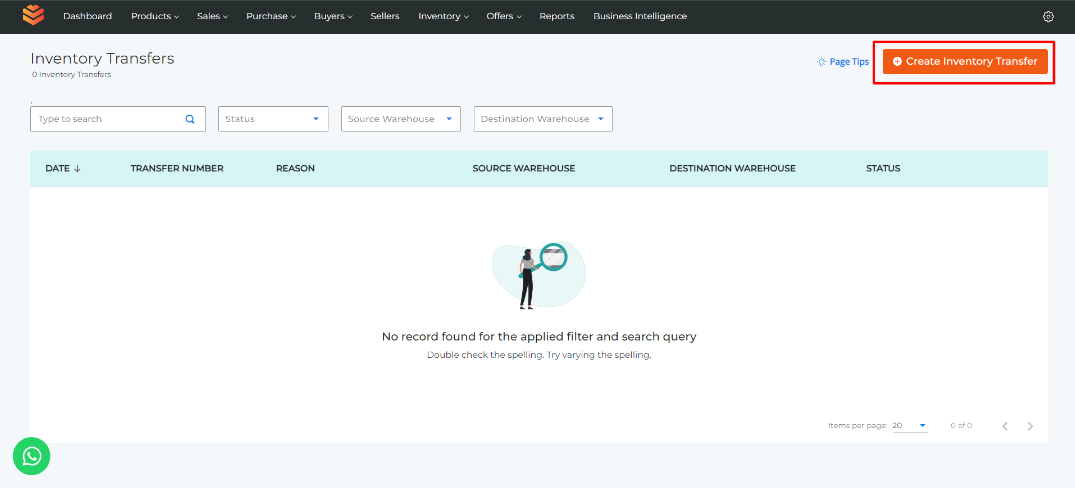

Step 2: You would see a list of transfers that already have been created. Select the create inventory transfer button from the top right corner.

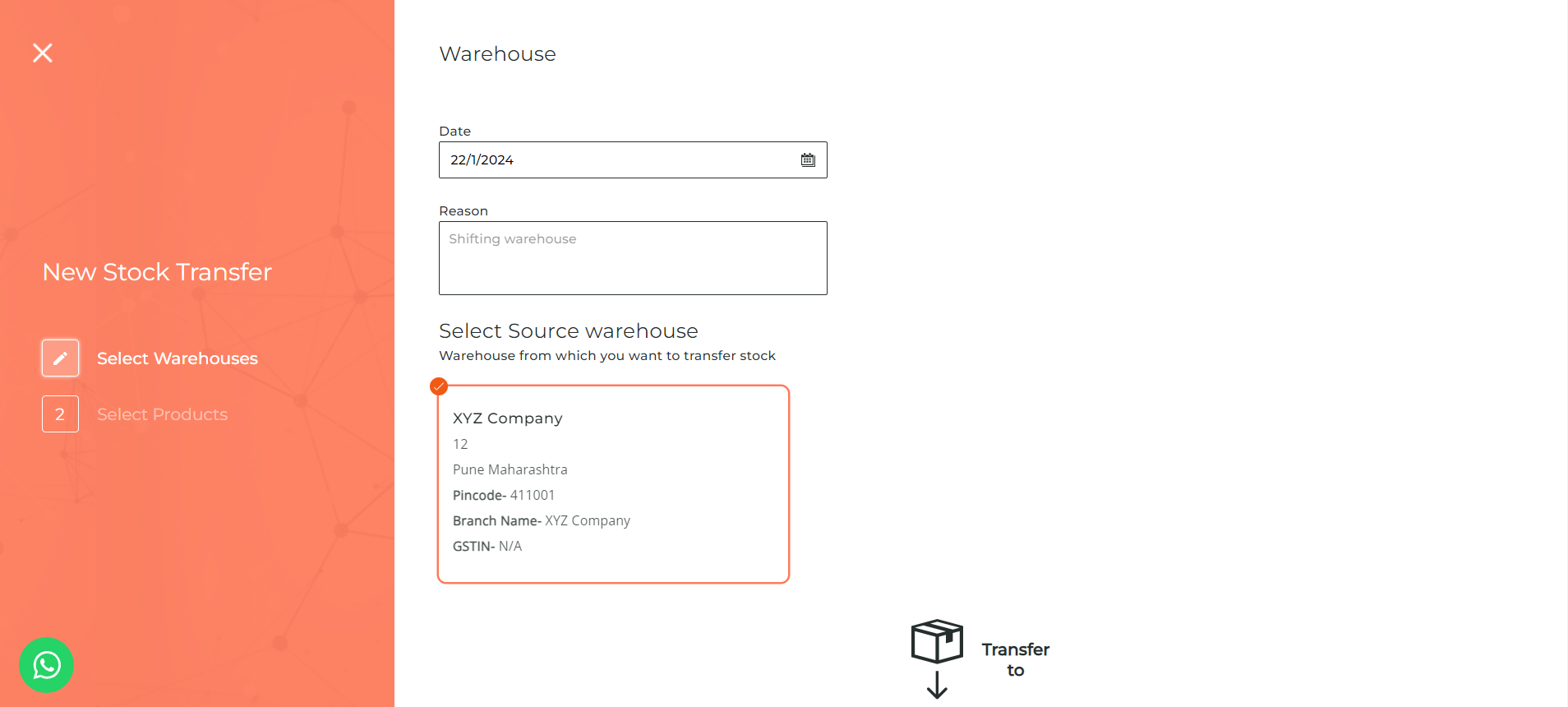

Step 3: You would have to select the date of transfer. Specify the reason for transferring if any, if not leave the field blank. Select the source warehouse from where you have to transfer the products.

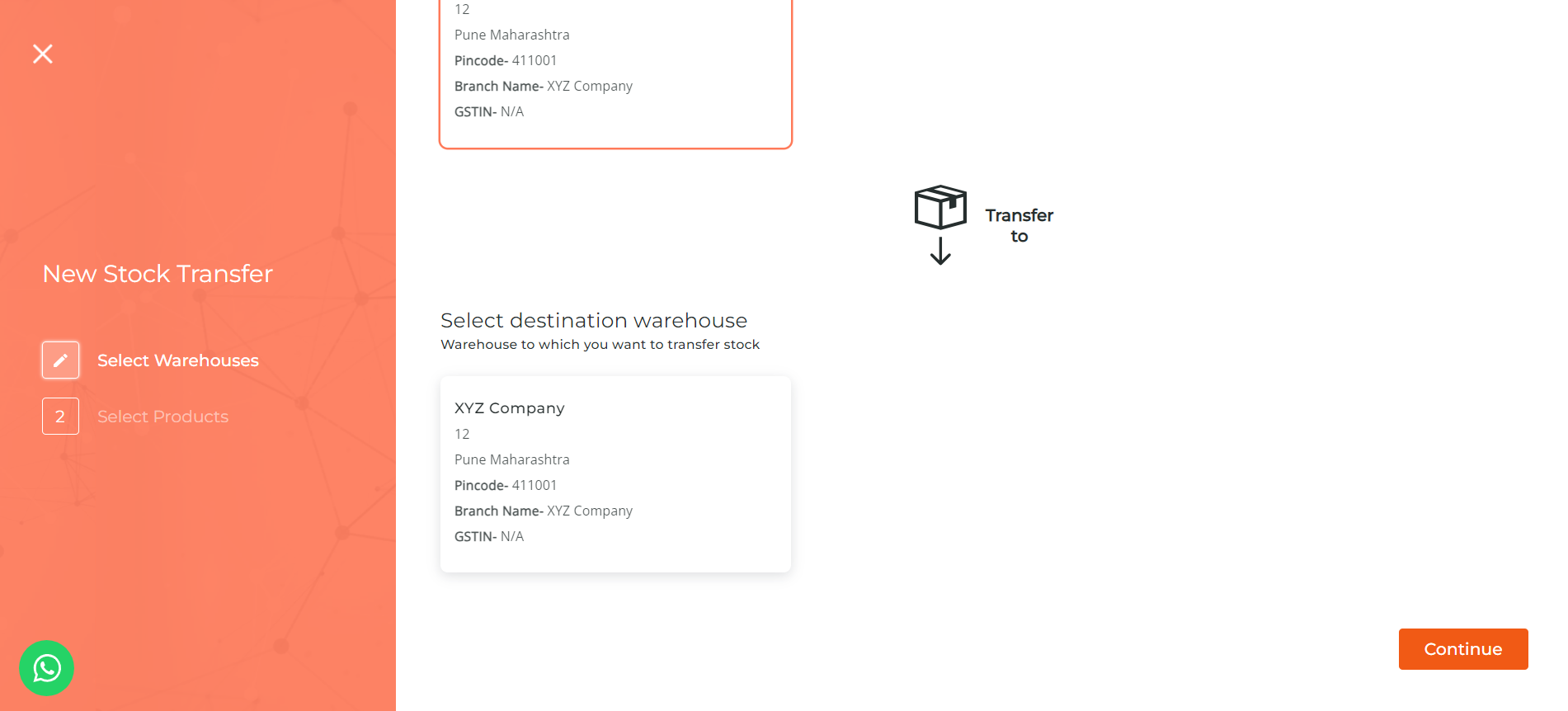

Step 5: Select the destination warehouse, where you have to store the products. Click the "Continue" button

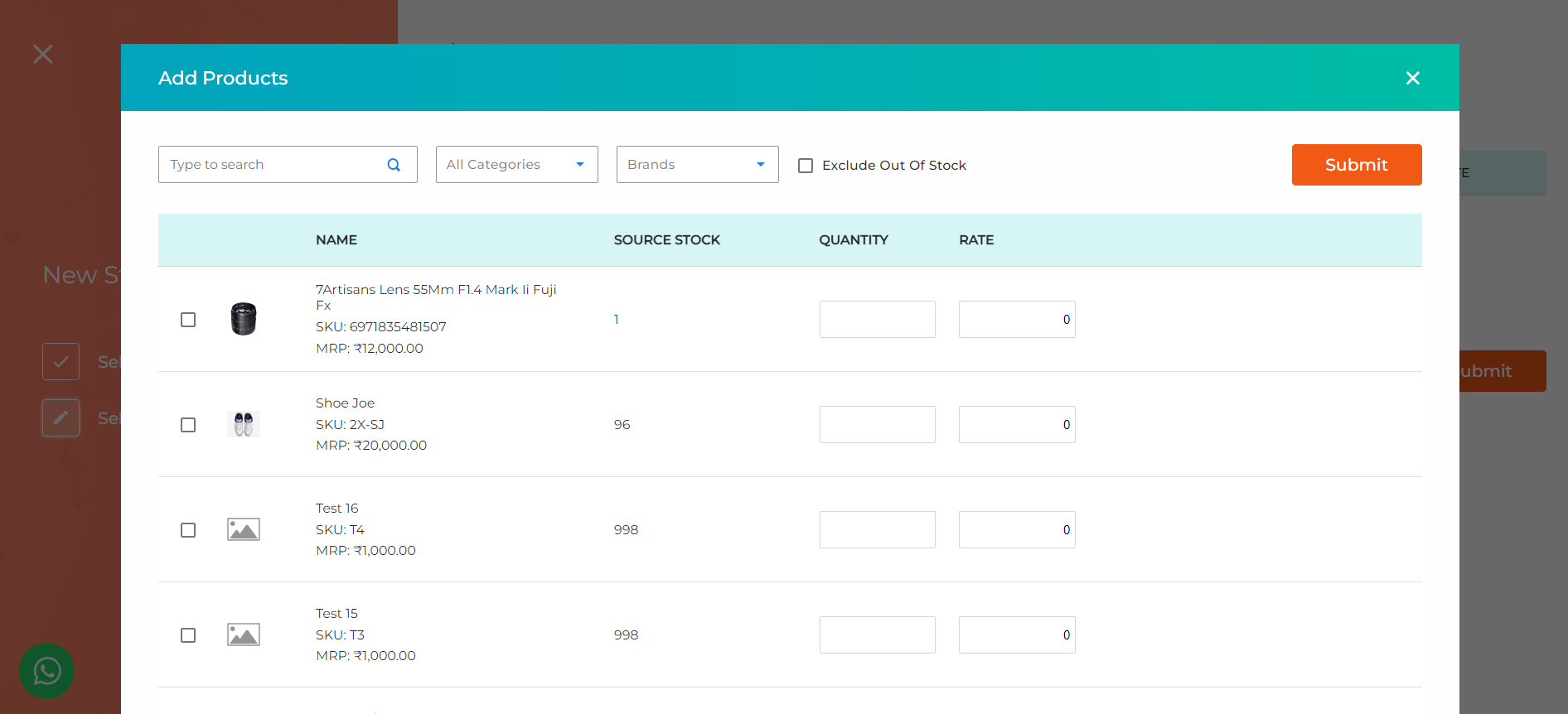

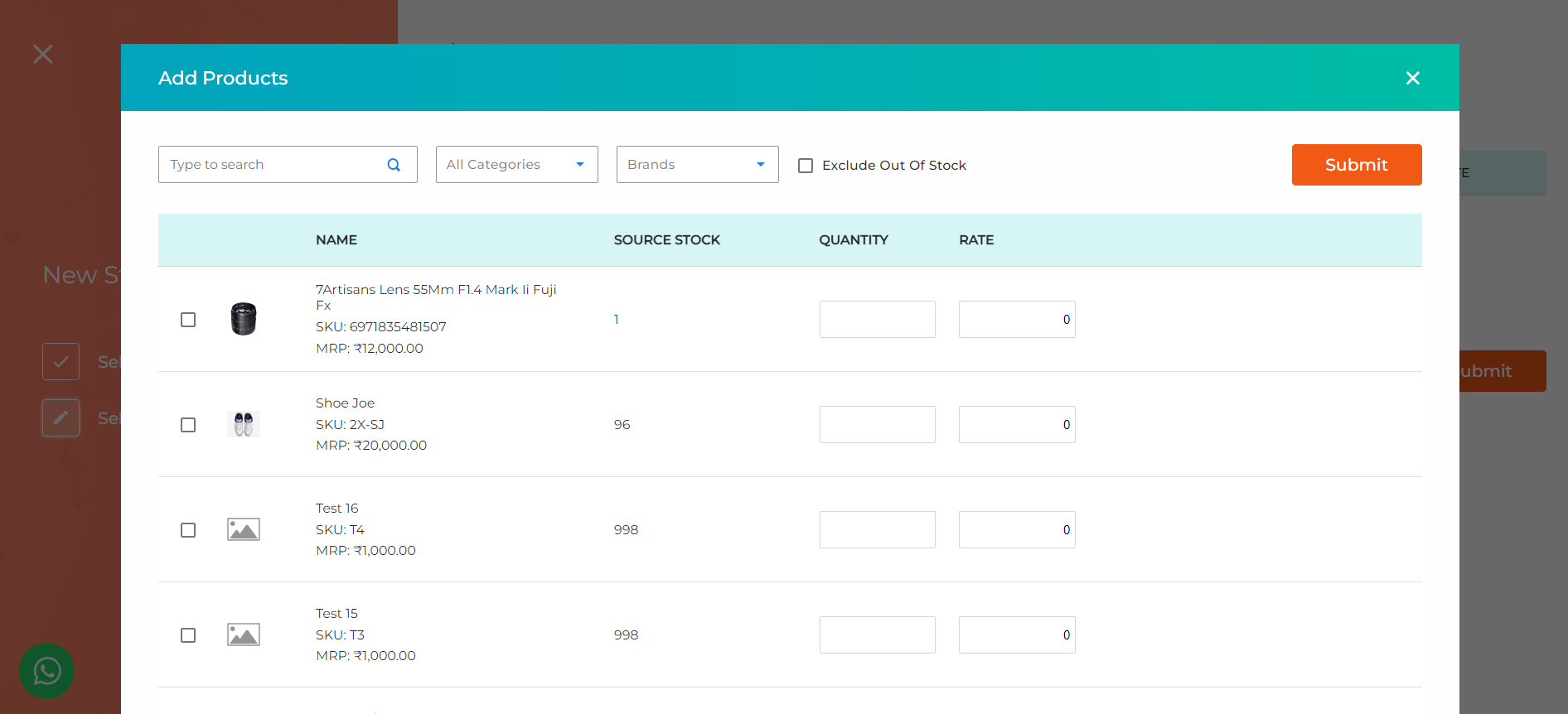

Step 6: Select products that you want to transfer from the source warehouse. Enter the quantity to be transferred. The quantity to be transferred should always be less than or equal to source stock and the rate of the product and click the submit button.

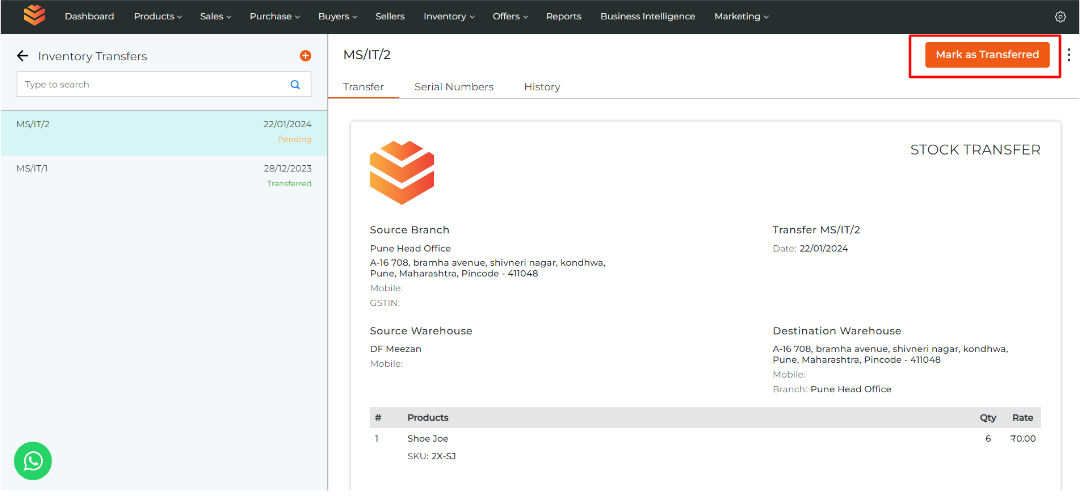

To complete the transfer you have to go to the transfer request and select mark as transferred.

Inventory Transfer will be created successfully.

Create an Inventory Adjustment:

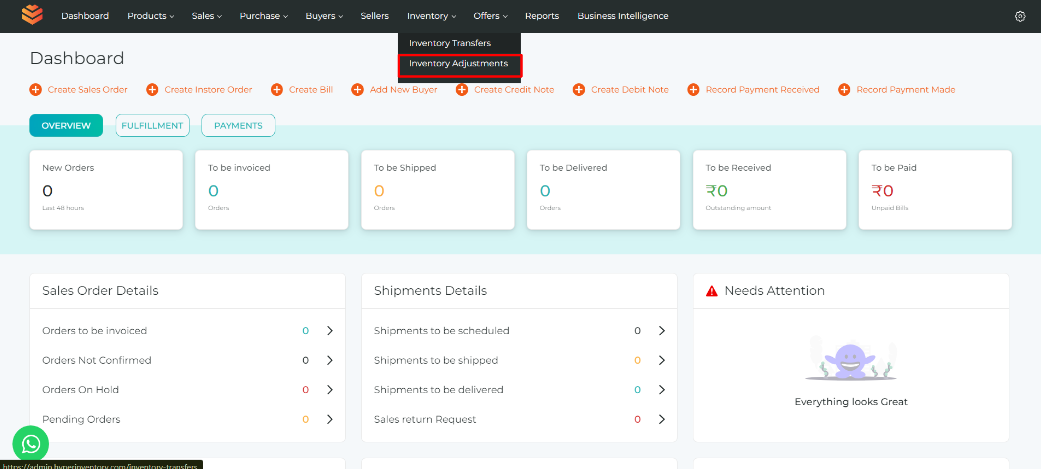

Step 1: Go to the inventory option from the top bar. Select the "Inventory Adjustments" option from the drop down menu.

Step 2: You would see a list of adjustments that were created. Select the "create inventory adjustment" button from the top right corner of the screen.

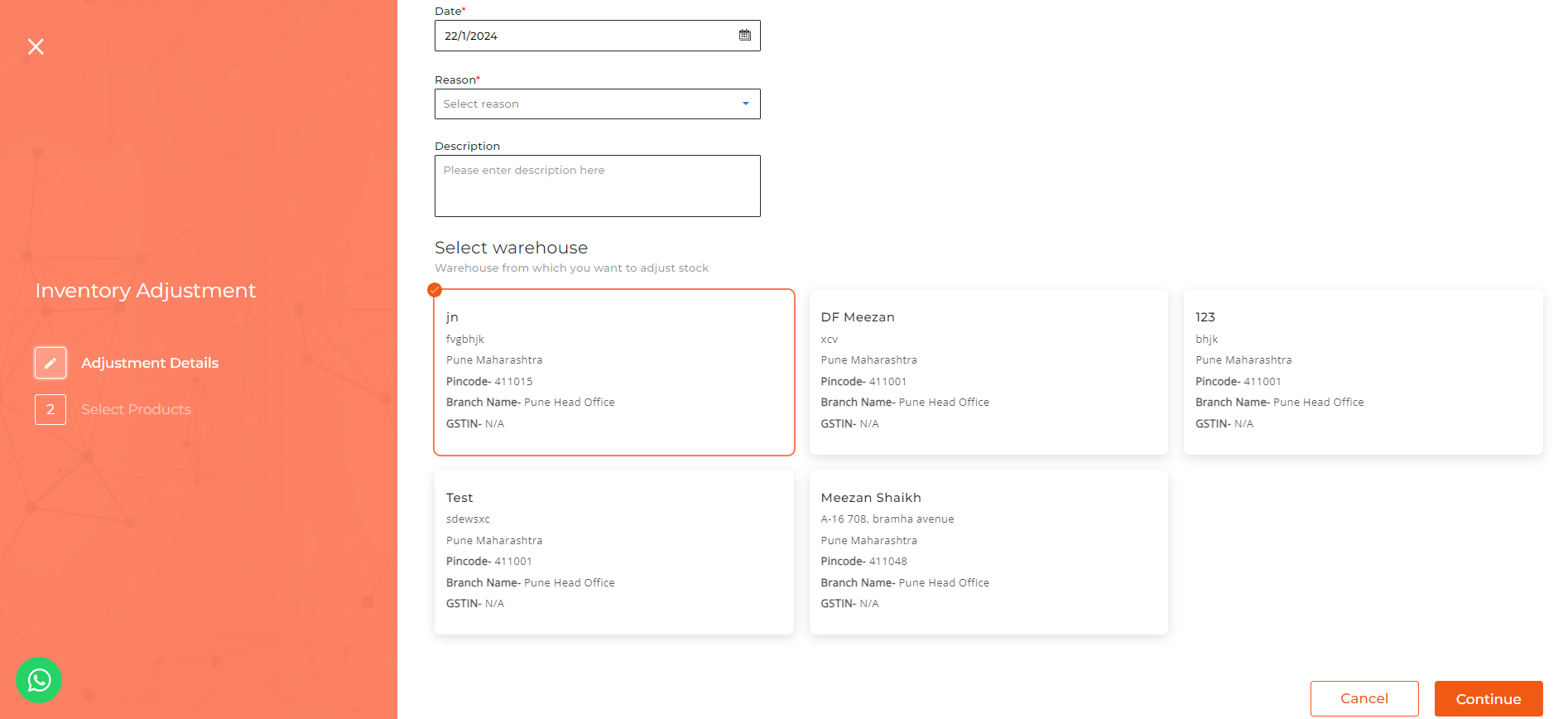

Step 3: Enter Inventory Adjustment Details

- Select the date of adjustment.

- Specify the reason for adjustment out of - Stock damaged, Stock stolen, Stock lost, Stock on fire, Stock outdated, Item return, Extra inventory found or Inventory Repaired

- Give details about the adjustment in the description box(optional).

- Select the warehouse for which you want to adjust the stock and click continue.

Step 4: Select the products in that warehouse that you want to adjust.

Enter the quantity to adjust. If you want to remove the quantity then add a negative ‘-’ value (ex: -100). If you want to add the quantity then directly enter the value (ex: 100). Add the rate of the product. Click Submit

Step 5: Click on "Create Adjustment" button.

The adjustment will be made successfully.

Benefits of Inventory Management with HyperInventory:

- Efficient Opening Stock Management: With HyperInventory, you can easily handle opening stock, tracking available quantities, and the status of products in multiple warehouses. This feature allows you to accurately record initial stock levels, acquisition rates, and monitor inventory management effectiveness.

- Automated Stock Calculation: HyperInventory automatically calculates metrics such as Stock on Hand, Qty to be Invoiced, Qty to be Shipped, Committed Stock, and Available for Sale. This automation saves time and ensures accuracy in inventory tracking, providing a real-time snapshot of your stock levels across all warehouses.

- Improved Financial Management: Tracking Qty to be Invoiced helps in better financial management by providing insights into pending invoicing and outstanding transactions. This allows businesses to anticipate cash flow and revenue more effectively.

- Enhanced Order Fulfillment: Monitoring Qty to be Shipped enables businesses to efficiently manage order fulfillment processes by keeping track of pending shipments. This ensures timely delivery of products to customers, enhancing their satisfaction and loyalty.

- Optimized Inventory Allocation: HyperInventory allows for the allocation of Committed Stock, ensuring that specific quantities of inventory are reserved for specific purposes or orders. This prevents overselling and ensures that stock is available to meet specific commitments or obligations.

- Accurate Sales Potential Assessment: The Available for Sale metric provides a clear indication of the inventory available for general sales, helping businesses gauge their immediate selling potential accurately. This information is vital for planning marketing strategies and managing sales operations effectively.

- Streamlined Inventory Management Processes: HyperInventory offers features such as bulk inventory management, inventory transfers, and inventory adjustments. These functionalities streamline inventory management processes, making it easier to update, adjust, and transfer inventory between warehouses efficiently.

- Improved Decision Making: By providing comprehensive insights into inventory levels, transactions, and stock availability, HyperInventory empowers businesses to make informed decisions regarding procurement, pricing, and resource allocation. This leads to better inventory control and strategic planning.

Overall, HyperInventory offers a comprehensive suite of inventory management functionalities that help E-commerce businesses streamline operations, improve efficiency, and optimize inventory control, ultimately leading to increased profitability and customer satisfaction.